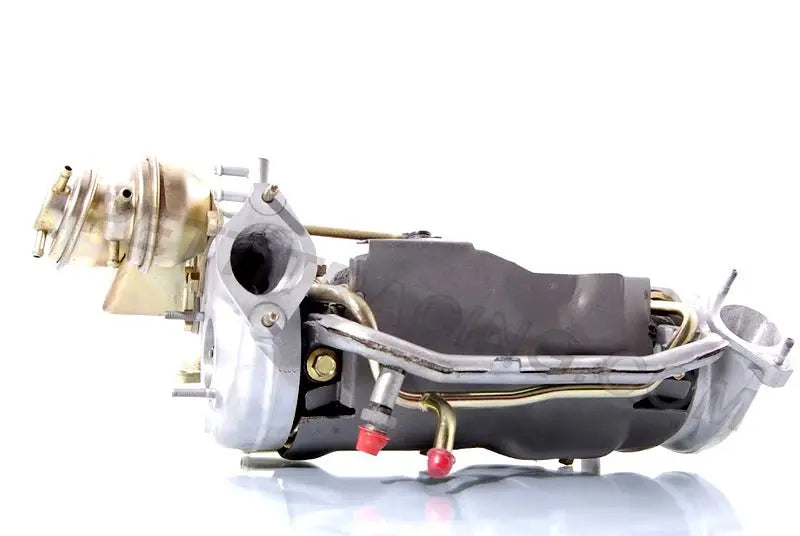

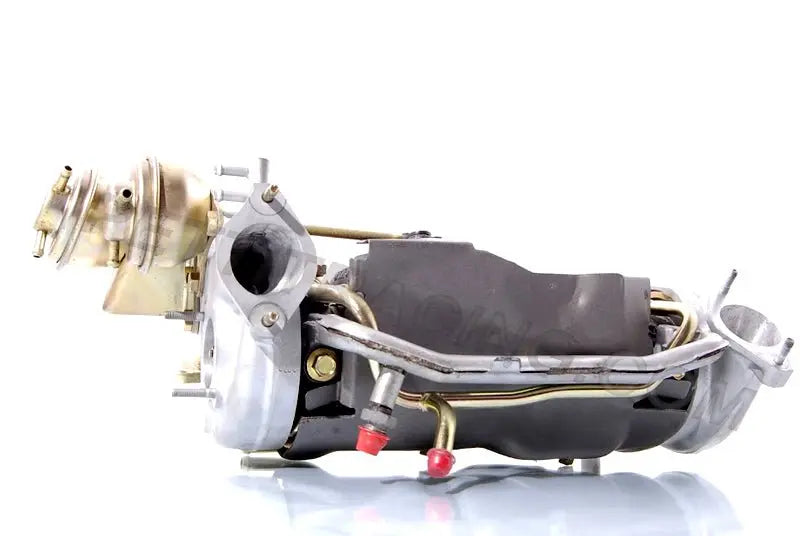

Pettit Racing Blueprinted Hi-Flo Twin Turbo Unit for Mazda RX-7 FD 1992-2002

Pettit Racing Blueprinted Hi-Flo Twin Turbo Unit for Mazda RX-7 FD 1992-2002

Couldn't load pickup availability

Our blueprinted Hi-Flo or BPHF twin turbo unit is a complete, ready to go, modified OEM RX-7 FD twin turbo.

These turbos are far superior to the stock unmodified unit where mass production practices leave sharp edges directly in the exhaust path creating hot spots that can cause cracks. With our units, the exhaust housings are ported and contour radiused creating a bevel on all those unfinished edges, this reduces hot spots minimizing chances for heat cracking. Aside from improving longevity this procedure also improves the flow path and efficiency of the unit. To help reduce the under hood temperature a ceramic thermal barrier coating is applied to the hot section as well.

We also port and blend the tapered discharge outlet on the compressor housings which improve efficiency and spool up*.

The complete turbo assemblies are then fixture assembled ensuring proper alignment.

All this results in a much-improved RX-7 twin turbo unit that has proven itself by providing both reliability and superior performance for our customers since 1994. This same basic turbo was used in our road racing Mazda RX-7 to win the 1998 GT2 Championship!

Nearly every RX-7 twin turbo we receive has cracks, and we have seen many attempts to weld them but all have failed. The weld material eventually comes loose destroying the exhaust turbine wheel on its way through the turbo.

We have found over the years that old existing cracks are no longer a problem after our modifications are done and we have never seen a crack related failure of our turbo housings. This is because our procedures minimize the hot spot areas, reducing the heat loads that cause the cracks. This alone makes a huge improvement in longevity, but then we apply a ceramic coat to the unit further improving thermal performance.

One of the most important things we have found is getting a proper install of the turbo unit. Using anti-seeze on all the threads and proper torque on all the fasteners is a must. Then after several good heat cycles we re-torque the fasteners. It is also a good practice to re-torque the fasteners after track events as well as twice yearly.

Warranty 12 months from purchase date, If the part fails for any reason we will replace it free. We only provide the replacement part; we do not pay for shipping, installation labor or anything else.

We offer the same modification and blueprinting service for your turbo and/or manifold. Typical cost to build your turbos ranges between $1800-$2950 depending on the condition of the turbo and the parts required to refresh it to usable standards. Each turbo unit or manifold we receive is disassembled, inspected and quoted, prior to any costs being incurred.

Our BPHF turbo units even seem to have improved spool time over the 99 J spec turbo unit with abradable compressor housing inserts. This design, where the compressor wheel is in contact with the insert is thought to be more efficient due to closer tolerances, however, this contact can generate friction and may cause slower spool times.